Propeller MaintenancePropellers are considered wear items and should be inspected before every dive during the Pre-Dive Setup procedures.

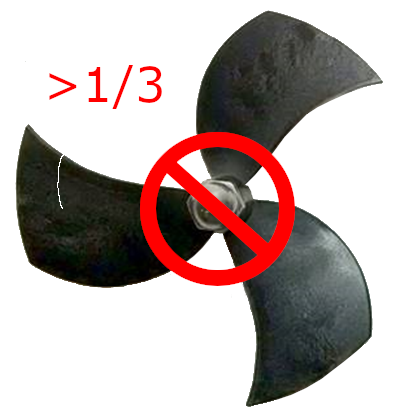

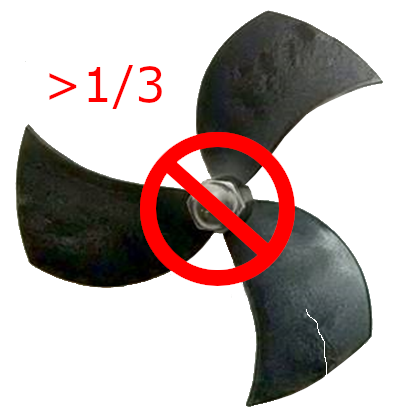

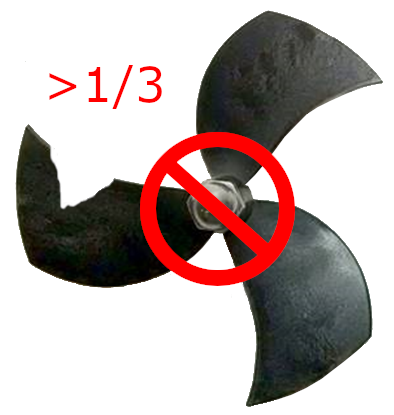

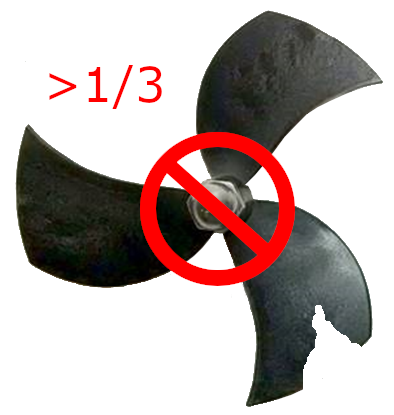

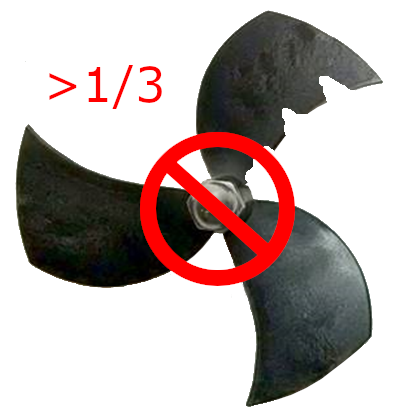

Propeller Replacement GuidelinesPropeller replacement can be based on a rigid pass/fail criteria, such as when a propeller blade breaks off and is missing, in which case the propeller should be replaced immediately, or based on a risk assessment when the propeller has mild to moderate wear. Such a risk assessment should consider the importance and urgency of the mission. If the mission is critical, deep or it would be difficult to retrieve the ROV in the event of a control failure due to the loss of a propeller, such as operating in a confined space, a propeller that exhibits even mild wear should probably be replaced. If the mission is brief, shallow and there is no risk of difficulty in retrieving the ROV by its tether, then even moderately worn propellers can remain in service. The following guidelines are provided to help determine whether propellers should be replaced or not. Propellers should be replaced if any of the following conditions are observed:

Generally Acceptable Propeller WearGenerally, any propeller that has a ragged edge can be used as long as it does not affect vehicle performance or control. Loose pieces or pieces bent out of the plane of the propeller should be removed using sandpaper or a file.

Propeller Replacement ProceduresPropellers are connected to the thruster shaft using a drill chuck-like collet that has a fluted tapered core that compresses on the shaft when the propeller nut is tightened.

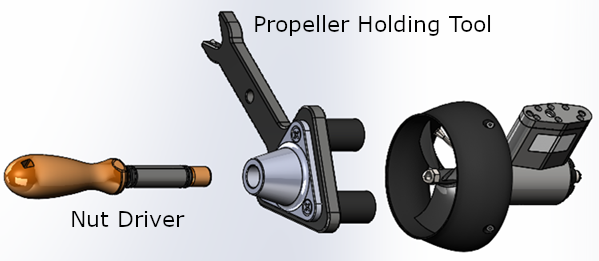

Propeller RemovalTo remove a propeller, loosen, but do not remove the nut using the propeller holding tool and 7/16" nut driver. The collet should then be free to slip out of the hub, open and release from the shaft. The propeller can then be pulled off the shaft.

If the propeller cannot be removed from the shaft, contact VideoRay Support for additional recommendations. Propeller Replacement

See the Thruster Arrangement configuration table for the correct propeller type selection for each thruster.

After selecting the correct propeller pitch for its installed location, loosen but do not remove the propeller nut and install the propeller on the thruster shaft until it is seated. Using the propeller holding tool and 7/16" nut driver, tight the propeller nut. The nut should be tightened as much as possible (assuming a person with average strength) to prevent it from slipping off during operations.

|

Mission Specialist Pro 5

Operator's Manual

Operator's Manual