Module ConfigurationThe modular concept requires that modules be configured prior to installation or replacement in a specific vehicle arrangement.

Conceptual OverviewThrusters and other modules can be thought of as employees, and the vehicle as the jobsite. Each employee (Module) has a unique name (Serial Number stamped or printed on the module and coded in the firmware). When the employee goes to work at the jobsite (is installed on the vehicle), it is assigned an employee number (Node ID) by the person doing the configuration. The jobsite supervisor (control software) communicates with the employees using their employee number, so the employee number for each module on a jobsite must be unique. Work instructions are announced to all employees at the same time, so each employee must listen for their specific instructions and ignore the instructions for other employees. When there are multiple employees of the same type on a jobsite, these employees may be assigned specific work tasks (Application ID or Motor ID). The employee will only listen for instructions related to their work task. For example a starboard thruster will only respond to horizontal control inputs, while a vertical thruster will only respond to vertical control inputs. This approach allows vehicles to be configured with great flexibility. Examples include:

General Requirements

The following sections provide information about module replacement. |

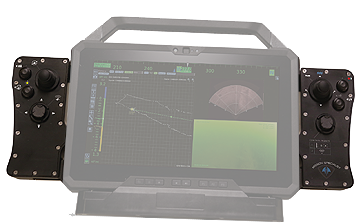

MSS Defender

Operator's Manual

Operator's Manual